Reconciling Inventory

This article supports Legacy Inventory, previously known as Systemize Inventory Edition, which is supported but no longer available for purchase.

Click here inventoryhelp.moraware.com to access the new Moraware Inventory Knowledge Base.

Your Inventory is going to drift out of sync from time to time. Fixing discrepancies on a regular basis will keep you confident your Systemize Inventory is current and useful.

To reconcile your Inventory compare what you have in your system to what you have in real life. When something is missing in real life or in your system, figure out why and update the system accordingly. Every time a slab is ordered, received, moved, or consumed in real life, record the same action in Systemize Inventory. Performing periodic reconciliation can help you improve your process to prevent mistakes from happening in the future.

The first reconciliation you do will take time. After that, decide the frequency that will work best for you. Some fabricators opt for an all-encompassing reconciliation once a month. Others prefer to assign someone to reconcile just one location each day, a "rolling" reconciliation. Once everything is up to date, it's easier to keep it reconciled moving forward.

The following example assumes you're using Serial Numbers for your slabs. If you're not, email us to discuss: support@moraware.com.

MANUALLY RECONCILING SYSTEMIZE INVENTORY EDITION

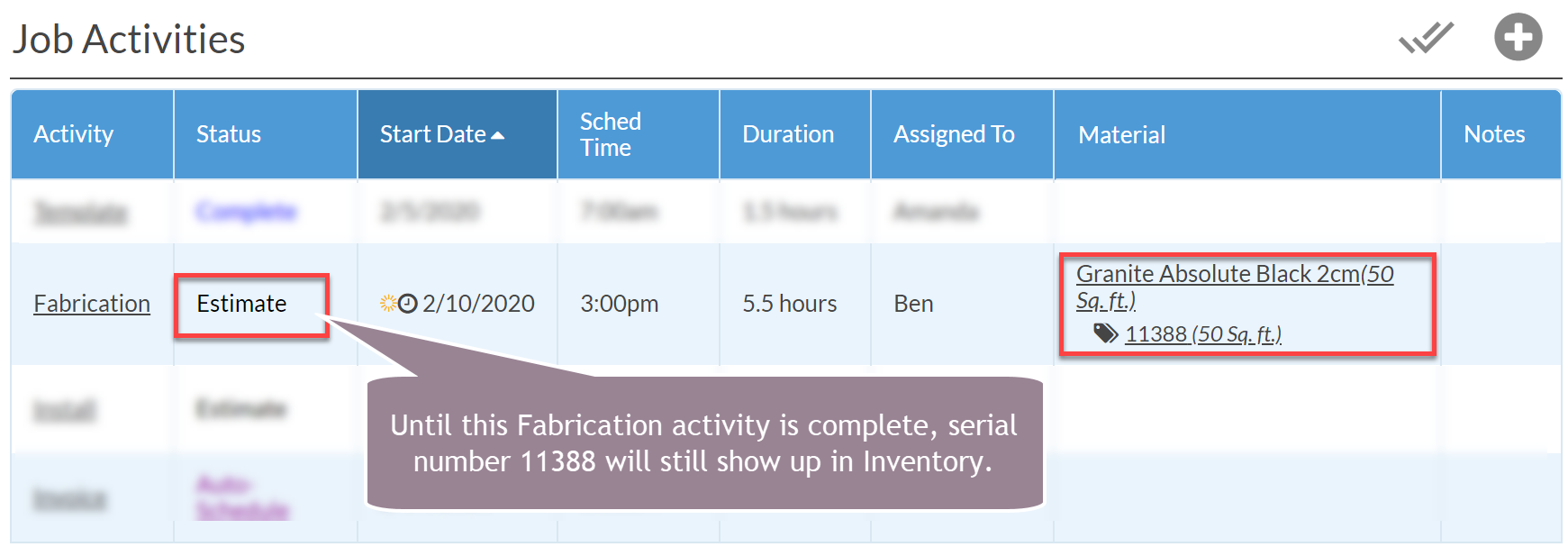

- Most important is to be certain you have completed all Activities in Systemize that are actually done, especially the ones with Material Allocated. This is important, because if you have a Serial Number assigned to a Job Activity, but the Activity is not marked complete, then it will still show in Systemize Inventory.

- Look for Unserialized Product Variants with Allocated Material or Serial Numbers with negative amounts. That's a sign of mismatches in your Allocations. Email us for help fixing those. Fixing them is the only way to have your Inventory correct.

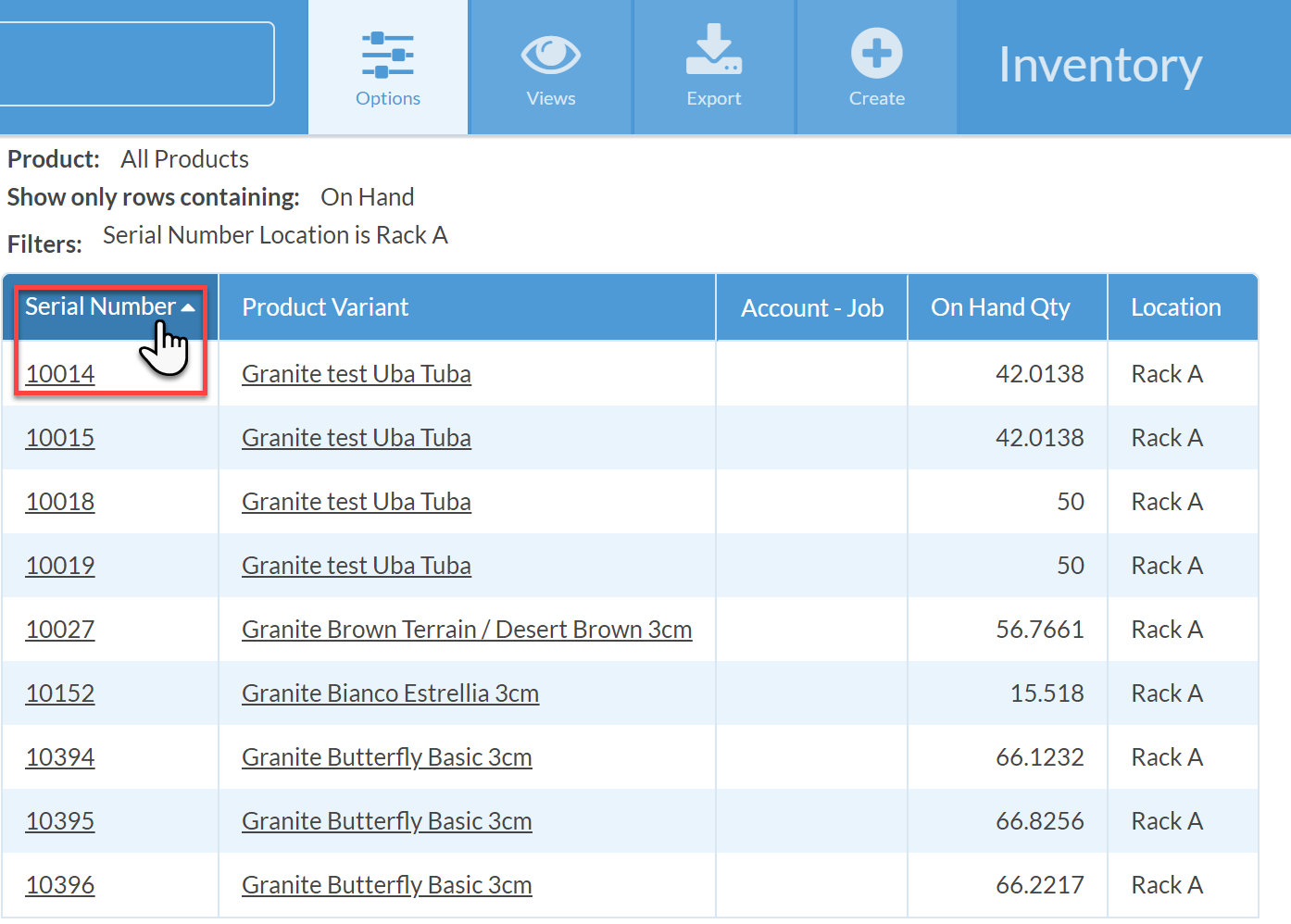

- Create an Inventory Detail View with the columns that are most useful to see when you reconcile.

Start with Serial Number, Product Variant, Account - Job and Location. Consider adding Measurements, Is Remnant, Batch Number and others that are useful to you.

You'll probably want to show only On-Hand Inventory.

Add a Filter to break down reconciliation into manageable chunks. Locations are really useful for this. You might consider organizing your Location names based on how much you can reconcile in one session.

- Sort the View by Serial Number. You'll be looking for specific Serial Numbers on your list, so they need to be in order.

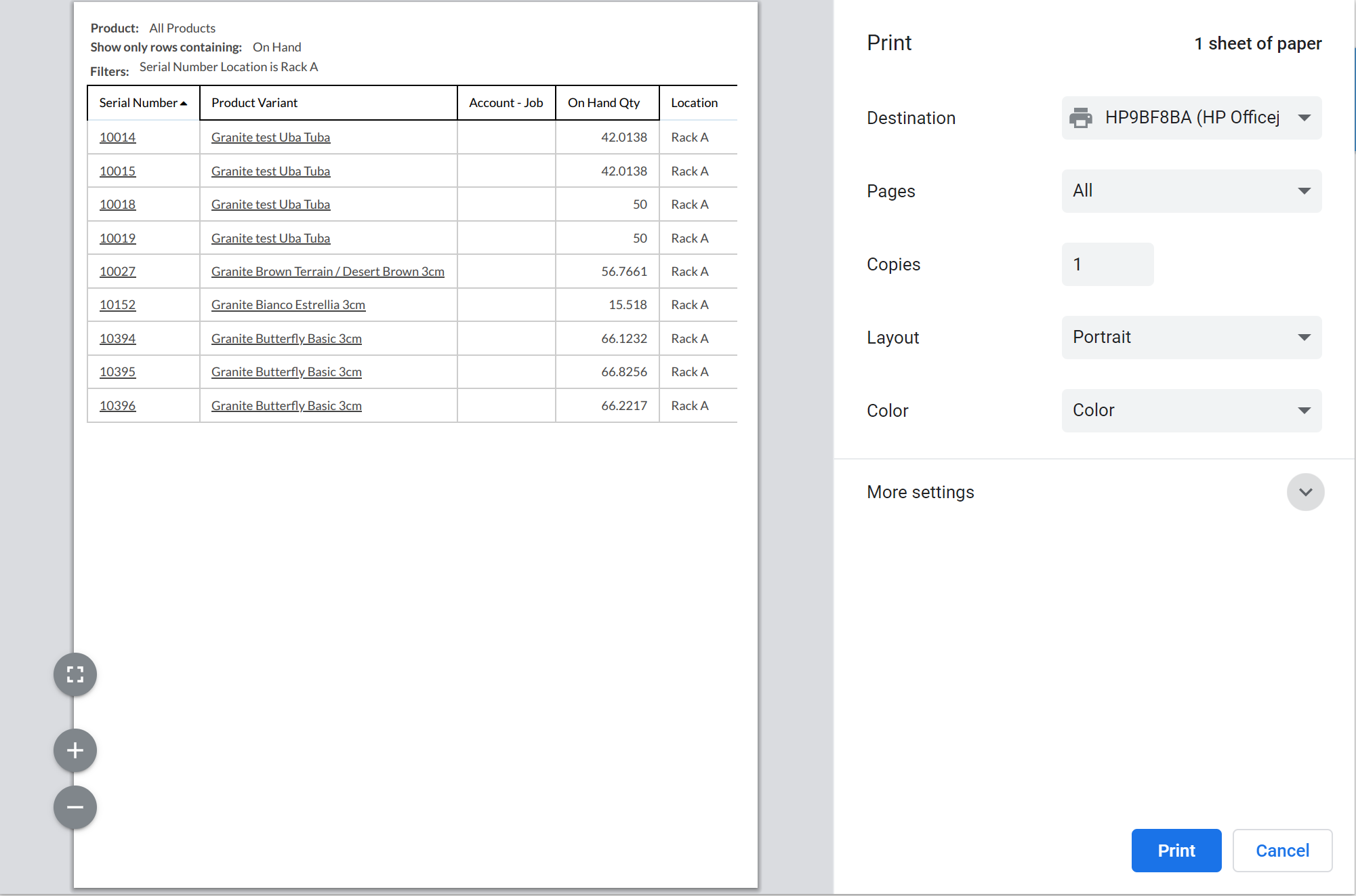

- Print out the View using your browser settings.

- Begin comparing the slabs in your yard to the printout, completing one location at a time. Check off slabs in the yard from the list. If you have slabs in the yard that are not on the list, make a note of their Serial Number and Location.

- When you finish comparing, if every Serial Number is checked off and no new ones are noted, you're done!

-

If a Serial Number on your sheet isn't checked off, that means it's in the system but not at that location in real life.

- Search for the Serial Number. Is it assigned to a Job that's been finished in real life? Should it have been?

- View current Inventory for the Product Variant. Were neighboring slabs used on other Jobs? Was the missing slab used for one of those Jobs?

- Look through the other physical locations for that particular slab. If you find it, update the Location for the Serial Number. Coach your team on the importance of updating Systemize Inventory when slabs are moved.

- Was the slab broken? If so, make a new remnant for any remaining usable pieces. See Related Articles below for help dealing with broken slabs.

- Was the slab stolen? This is the worst case, but it's part of the reason you reconcile. Reconciling can't eliminate theft completely, but it helps you identify it as quickly as possible.

-

If you have noted slabs that are in the yard that are not on the printout, do some investigating in your Systemize Inventory database.

- Search for the Serial Number. If found, does it simply have the wrong Location? If so, fix it.

- Look at the current Inventory for that slab's Product Variant. Was the slab misnumbered?

- If the slab was never entered, then create a Purchase Order using a Fake Supplier and write the correct Serial Number on the slab. See Related Articles below for more on creating and using a Fake Supplier.